Home Sherwood Tinning Ltd

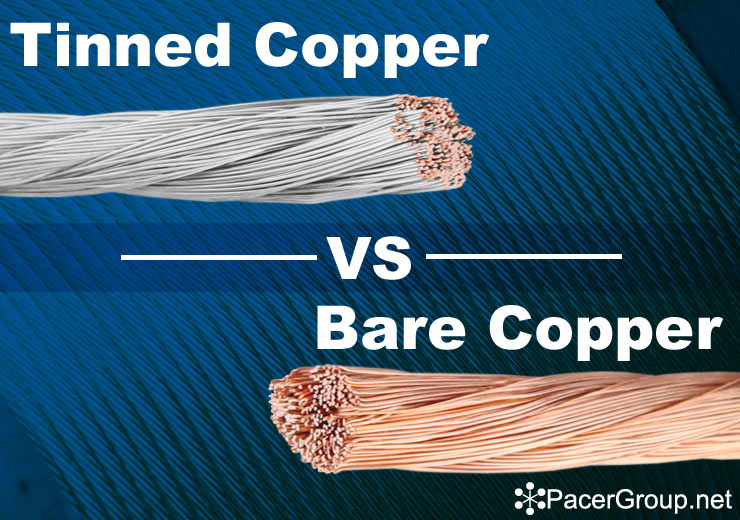

Copper is a desirable material because it is highly conductive. However, copper is also highly susceptible to oxidation or erosion. Tin has properties that make it more durable than copper. Coating bare copper wire in tin gives the wire the conductive properties of copper while using the tin to prevent oxidation and protect the copper.

STRANDED BARE COPPER WIRE & TINNED COPPER WIRE

Keeping your copper pans in perfect condition after retinning 1.) Do not "preheat" copper pots. Since copper conducts heat so well, it heats up very quickly. The tin lining can and will melt in as little as 30 seconds depending on the size of the pan. 2.) Avoid scouring the tin. The tin lining will definitely change color over time.

800DTB Wire Bunching Machine For Bare Copper Wire Tinning Wire Tinned Wire

Tinning copper wire is an efficient way for protecting electrical wiring from corrosion and oxidation. It also makes soldering much easier and improves the appearance of the wiring. Tinning involves coating the wires with a thin layer of solder so that the wire itself becomes enclosed in a protective sheath. This helps to extend the life of the.

Tinned Copper VS Bare Copper Pacer Group

Over this tinning, which must cover the copper in an even and uniform, manner throughout, a second harder coat must be applied, as the first forms only a kind of medium for connecting the second with the copper. For this second tinning you employ pure grained tin, mixed with zinc in the proportion of two to three, which must be applied also.

NEWLYN TINNING NEWLYN TINNING RETINNING COPPER POTS & RETINNING

King copper with a tin crown. Copper wins, because of conductivity and cost. And because oxygen is the cause of corrosion, manufacturers super-heat their copper to burn away any air before encasing it in protective tin coating and insulation. That's why we like tinned 100% oxygen-free copper wire the best for all our wiring.

Tinning Copper Pans YouTube

Tinned Copper Composition. At its core, tinned copper consists of two elements: copper and tin. Copper is an incredibly versatile metal that's highly conductive, meaning it absorbs and transfers electricity very quickly. Tin acts as a protective agent for copper, providing resistance against corrosion and other environmental factors.

An Overview of Tinning Copper Wire

What exactly is happening during the tinning process when creating tin-lined copper cookware?Here's a brief explanation of flux, handle heat conductivity and.

East Coast Tinning Copper Pots, Vintage Copper, East Coast, Girls

After stumbling upon a worn out copper stockpot in 2003, Jim Hamann brought it home, determined to learn how to restore and use it. As a mechanical engineer fascinated with cooking, he began retinning the piece, watching the transformation unfold. Soon, he was hooked, and by 2006, he opened East Coast Tinning in East Greenwich, Rhode Island.

2 BARE TINNED COPPER WIRE Cable Management

This video describes how to tin copper and the sheet you'd like to solder. It goes through cleaning, marking, flux and solder. It shows how to create a lap s.

Tinning copper clad aluminum wire from China Manufacturer, Manufactory

So you want to tin some copper? Or you want to know what goes into preparing copper cookware for tin? Or at the very least, see and hear what I do? Here ya g.

DIY Hand Wiped Tinning of Old Copper Pots/Pans Step by Step

History. The practice of tinning ironware to protect it against rust is an ancient one. According to Pliny the Elder tinning was invented by the Gallic Bituriges tribe (based near modern Bourges), who boiled copper objects in a tin solution in order to make them look as if they were made from silver. The first detailed account of the process appears in Zosimus of Panopolis, Book 6.62, part of.

Home Sherwood Tinning Ltd

The cost of retinning copper cookware, which includes polishing, is $7.00 per inch. Larger items over an 18 inch total will be charged $10.00 per inch. To calculate the total inches of a copper pot or pan, add the diameter and the height together to get the total inches. Oval or rectangular pans total inches can be calculated by length + width.

Services Sherwood Tinning Ltd

The business of East Coast Tinning is restoring vintage copper cookware to make the pan usable again. The restorations consist of re-lining the interior cooking surface and polishing the exterior to a high shine. The cooking surfaces of vintage copper pieces are traditionally lined with tin. This tin lining slowly wears away over time with.

Tinning Copper Copper cookware, Copper, Cookware

Step Four: Polishing and detailing. The clean pan is checked for edge blisters in the new tin, which are ground flush. A texturing wheel is used to abrade the surface of the copper and orient its crystalline grain in a single direction. Thereafter, 3 - 5 steps of successively finer polishing and buffing wheels are employed to leave the.

Retinning & Polishing of Copper Cookware Rocky Mountain Retinning

The best solder to use for tinning stranded copper wire is electrical-grade rosin-core solder. This is an acid-free solder that contains a flux in the core of the solder. Never use solder that contains acid to strip and tin wires, as this can damage the wire or its insulation. Acid-core solder is intended for use in plumbing applications.

Home Sherwood Tinning Ltd

Underground. Copper is the preferred metal for grounding conductors and electrodes. This is not only due to its high degree of connectivity, but also its corrosion resistance. In most soils, copper electrodes outlast alternates such as galvanized steel. However, there are certain conditions where tinning (coating with tin) the copper would be.